Milestones

Expansion |

| 2024 |

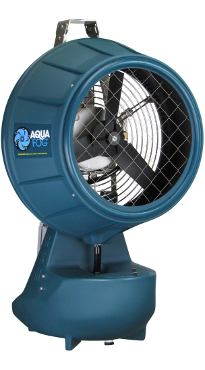

CoolAire MistThe biggest product venture thus far. Jaybird is proud to release its newest product: “CoolAire Mist” |

|

| 2023 2022 |

R&D begins into CoolAire MistConsidering entry into the market of Mist Cooling. People, gatherings and areas. R&D, testing and sourcing vendors begins. |

|

| 2019 2018 |

XE Hanging SumpIntroduction of XE Hanging Sump model. Model pairs with the GT Hanging Sump released earlier. |

|

| 2018 |

XE Rear Feed BladeInvestment into a successful injection mold becomes a game changer for the Turbo XE Series. |

|

Establishing Roots |

| 2017 2016 |

GT 500 & Stainless Steel UpgradeWe introduced a mid-sized product line and upgraded many components to 18-8 SST on all of our product lines. |

|

| 2015 |

Big Contract from U.S. GovernmentThis is our second major contract from the United States Air Force. Our equipment will maintain humidity in hangars for B-2 Stealth Bombers. |

|

| 2015 |

New Facility Aids in Marketing PushA new website and product videos headed up by key personnel, Dave Ritz and Miranda Dinsmore, advanced the company message. |

|

| 2013 |

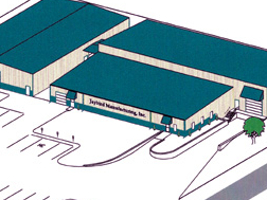

Construction of New FacilityWe broke ground on and completed Jaybird's new manufacturing facility. Darren led the project as the General Contractor. |

|

| 2012 2011 |

Building PlanningLots of planning and two years of paperwork eventually lead to the "go ahead" to begin construction. |

|

| 2008 2005 |

Aquafog 700 Product LineThe debut of Aquafog 400s in '05 allowed us to refocus on our products. The 400s were eventually upgraded in 2008 and relabeled "Hydro SS 700". |

|

| 2005 |

Injection MoldingThis was a BIG milestone for us! Acquiring the technology to produce our own in-house injection molds propelled our part production to a new level. |

|

Early Years |

| 2004 2000 |

Tool & Die InvestmentJaybird invested in a large press, a new machine shop, and the help of a die specialist, Victor Lutz, to produce our own injection mold dies. |

|

| 2000 |

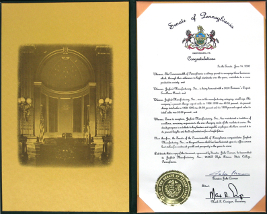

Exporting AchievementJennifer Wise was the driving force behind increasing our export sales from 1997-2000. As a result, we received an award from our state government. |

|

| 2004 1998 |

S. Korean Distribution PartnershipDarren traveled to Korea and arranged an import agreement. The smaller unit filled a product gap we had at the time. |

|

| 1998 |

Mobile HRSMThe new unit evolved into a series of three separate mobile units and quickly became a big addition to our product line. |

|

| 1997 |

Trade NameJaybird secured legal rights to the name "Aquafog" from the Patent and Trademark office in Washington D.C. |

|

| 1997 |

Front Page Local NewsJaybird's production floor made the front page of a local newspaper, leading a story that covered local exporting firms. |

|

Finding Direction |

| 1996 |

Industrial Park LocationWe moved Jaybird out of its residential location and established the company in the Woskob Industrial Park in State College, PA. |

|

| 1993 |

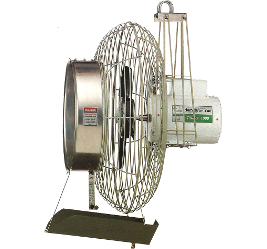

Debut of the Turbo XEThe Turbo XE had major improvements in fogging quality, waste water containment and size reduction. It remains our most popular product. |

|

| 1992 |

Rotational MoldingThis relatively new technology for the time elevated the product to a much higher performance level. |

|

| 1991 |

Humidifan TurboThis model featured a key engineering breakthrough that significantly reduced the size of the unit. |

|

| 1991 |

Jaybird's First ExpansionJaybird moved from a small garage (600 sq. ft.) into a much larger one that was constructed next door. |

|

| 1987 |

Jaybird & Humidifan 110Jaybird incorporated and debuted its first unit, the Humidifan 110. Unfortunately it didn't sell well and was taken off the market 12 months later. |

|

| 1987 1984 |

The First HumidifanDr. Daniel C. Milbocker built the first Humidifan in '84. He later received a patent on his invention from the United States Government in 1987. |

|