Need to Know FAQs

GT 500

Need to Know FAQs

- What is the difference? "Direct-feed" vs "Hanging Sump"

Direct-feed - Utilizes standard water pressure to feed water to the atomizing fan.

Pros - Fewer components; increased relilability, lower unit cost, a visual scale; needle valve flow control.

Cons - Requires drainage area for waste water control.

Hanging Sump - Uses a sump pump to feed water to the atomizing fan.

Pros - Recycles and conserves water, no drainage line.

Cons - Added unit cost and components, a quarter-turn ball valve replaces the visual scale; needle valve flow control.

- What is the fog particle size and will floors get wet?

Average particle size:

5-10 microns @ low volume

30 microns @ high volume

Particles measuring 50 microns or smaller will usually evaporate before hitting the floor. Natural fog averages 5 to 10 microns in size.

Whether your floors become wet or stay dry is largely dependent on the amount of fogging output, ambient air temperature, and the unit's mounting height. Use the adjustable flowmeter to find the optimum flow rate for your space.

Even the smallest fog particles can collide with others and result in fallout, and GT 500 also has occasional water drops fall from its housing. It's important to consider these factors when installing fogging equipment. We recommend suspending units up high where there is no sensitive equipment directly underneath.

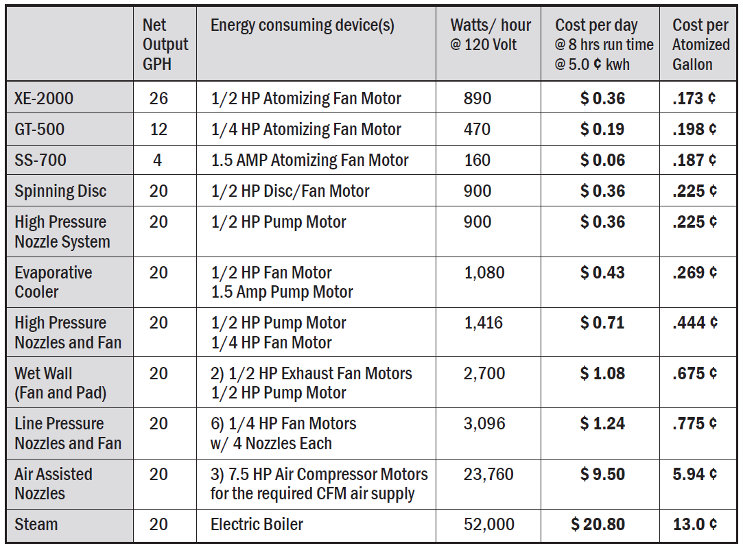

- How energy efficient is the GT 500?

Energy Consumption Comparison

- Where should the GT 500 unit be installed for best results?

For optimal performance, install the GT 500 high overhead, out of reach, and oriented to propel fog in the direction of airflow.

Allow adequate clearance directly in front of the fans; objects that are too close can become wet. Placing units higher allows more time for particles to evaporate as they fall, keeping floors drier.

If a GT 500 is mounted at least 7 ft above working height, the front safety guard can be removed, which improves fog quality.

- Should I use a control? Which control should I use?

We generally recommend using a control to automate the GT 500. We have a Humidistat, Thermostat, 24 Hour Timer, Cycle Timer, and Solenoid Control for the GT 500.

Humidistat: For maintaining 20%-80% relative humidity. Thermostat: For most evaporative cooling applications. 24 Hour Timer: For operation during only part(s) of the 24 hour day. Cycle Timer: Generally for high-humidity applications with little to no ventilation. Solenoid Control: For GT units either operated on a switch or run constantly. The Solenoid Control allows the operator to turn off the power and the water supply at the same time. The Solenoid Control also turns off the water supply in the case of a power outage. - How easy is the GT 500 to install?

The GT 500 is easy to install. The unit ships fully assembled, and all GT controls use a piggyback plug system. All you have to do is hang the unit, hook up the water supply and flowmeter panel, plug the unit in, and begin operation.

- Can I fog chemical solutions with the GT 500?

Yes. These units can be used for application of pesticides, herbicides, odor control products, and many other chemicals.

Any water-like chemical solution can be pumped up to the fogging head or gravity fed from a reservoir. Follow all safety procedures recommended by the chemical manufacturer.

- Can I use the GT 500 for cooling people at my outdoor venue?

The GT 500 will work well for most outdoor events, venues, and workplaces. The GT may not be appropriate for very quiet venues such as fine dining restaurants.